1981

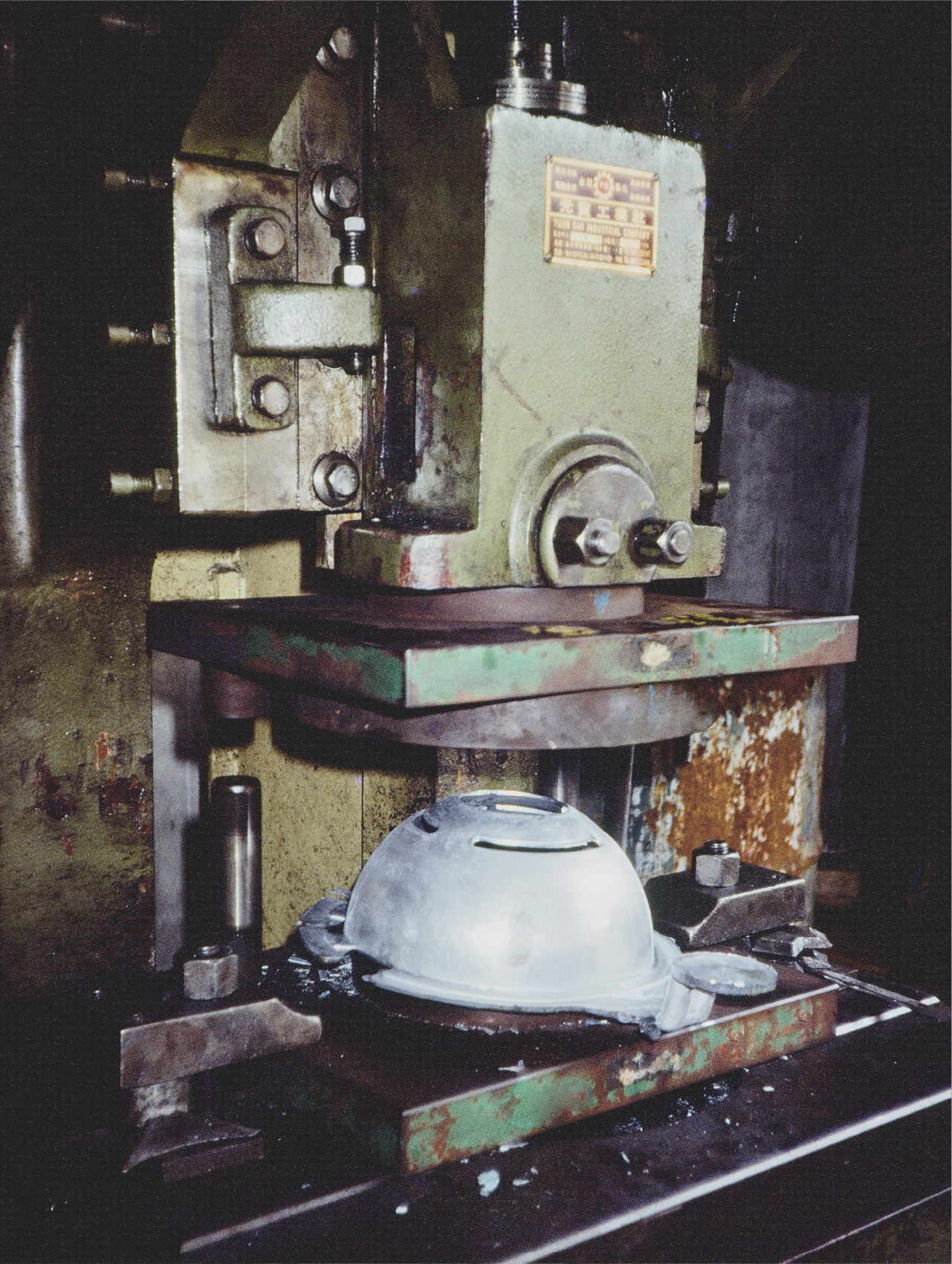

The Beating Hearts

Influenced by the distinctive style and design of the US ceiling fan, we started our manufacturing business from the core of the ceiling fan - the motor, which endows the most important core of the ceiling fan. We developed the traditional AC motor in 1984, and obtain the international quality patent certification, which is also the key factor for Halsey to start the manufacturing process of ceiling fans afterward.

1997

Quality Certified

We have passed the ISO9002 international factory manufacturing management certification, and our whole product series passed UL, ETL, TÜV, and other well-known international certifications in 1997. As the leader of the ceiling fan manufacturer industry, we’re also the first company to set up a professional laboratory which in accordance with UL certification and lead the company's quality certification internationalization.

1991

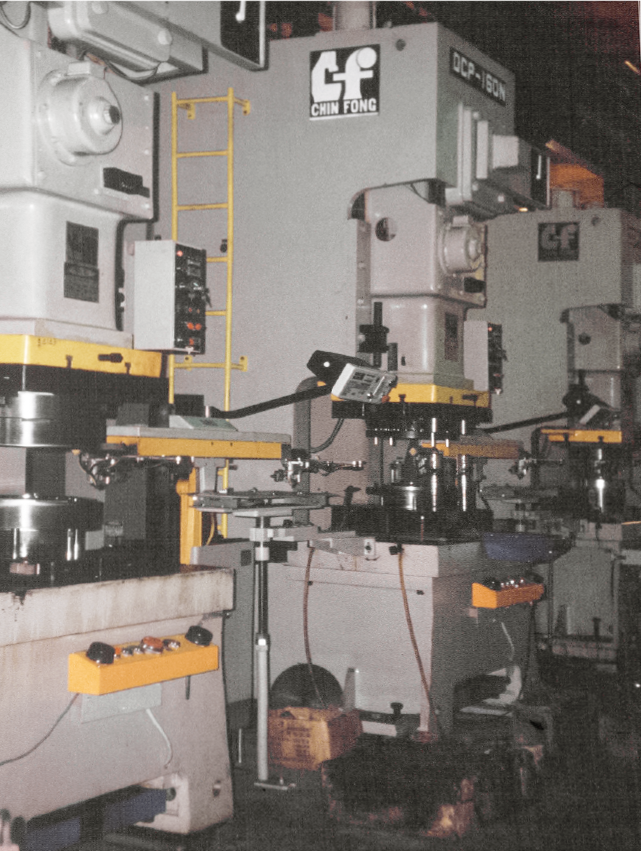

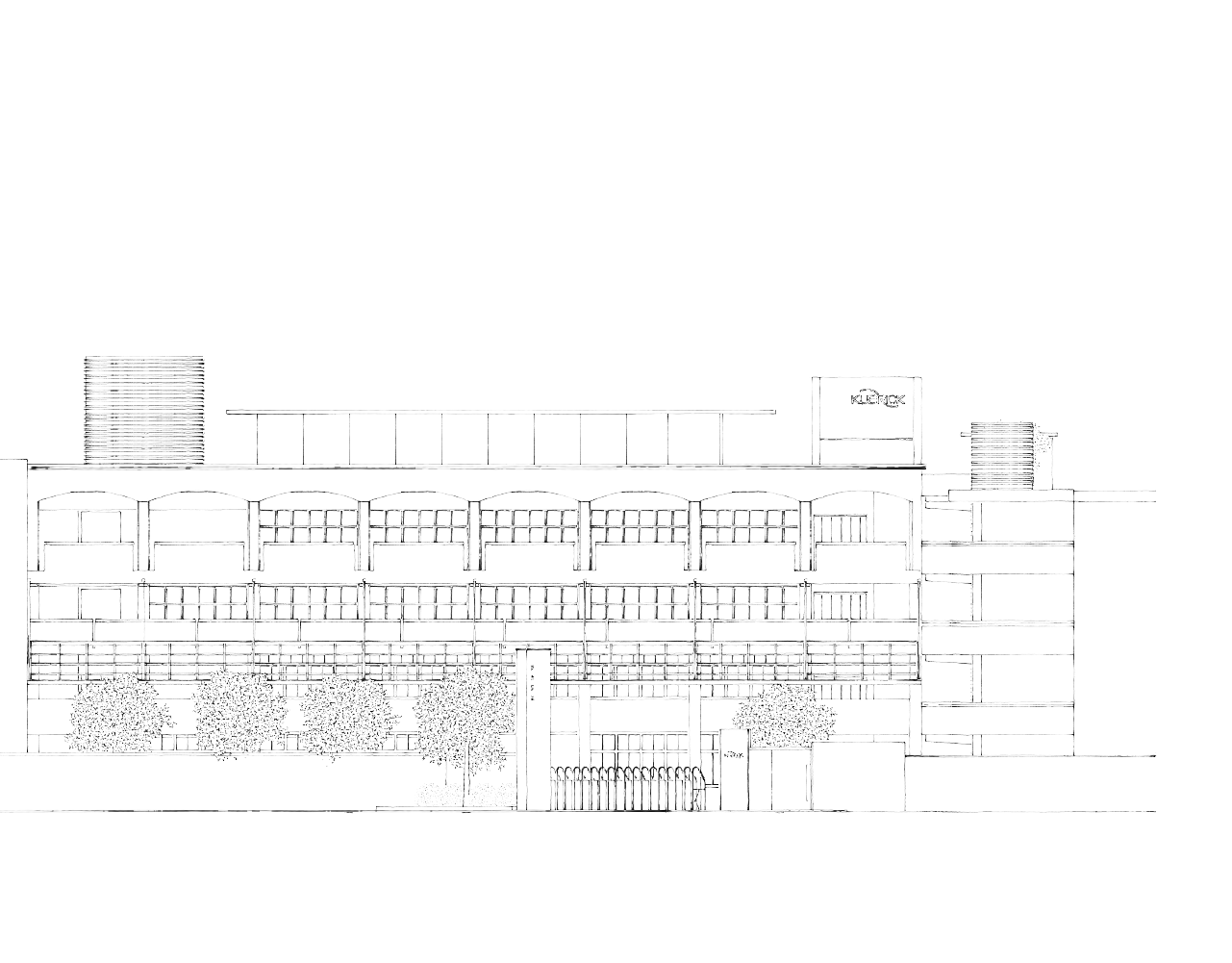

The New Extension of Halsey

In order to improve our production efficiency and meet the demand of the European and American markets, a new factory was completed in 1991, which introduced more automated machinery and equipment to enhance the efficiency of the manufacturing process and develop a more comprehensive approach to our business.

1990

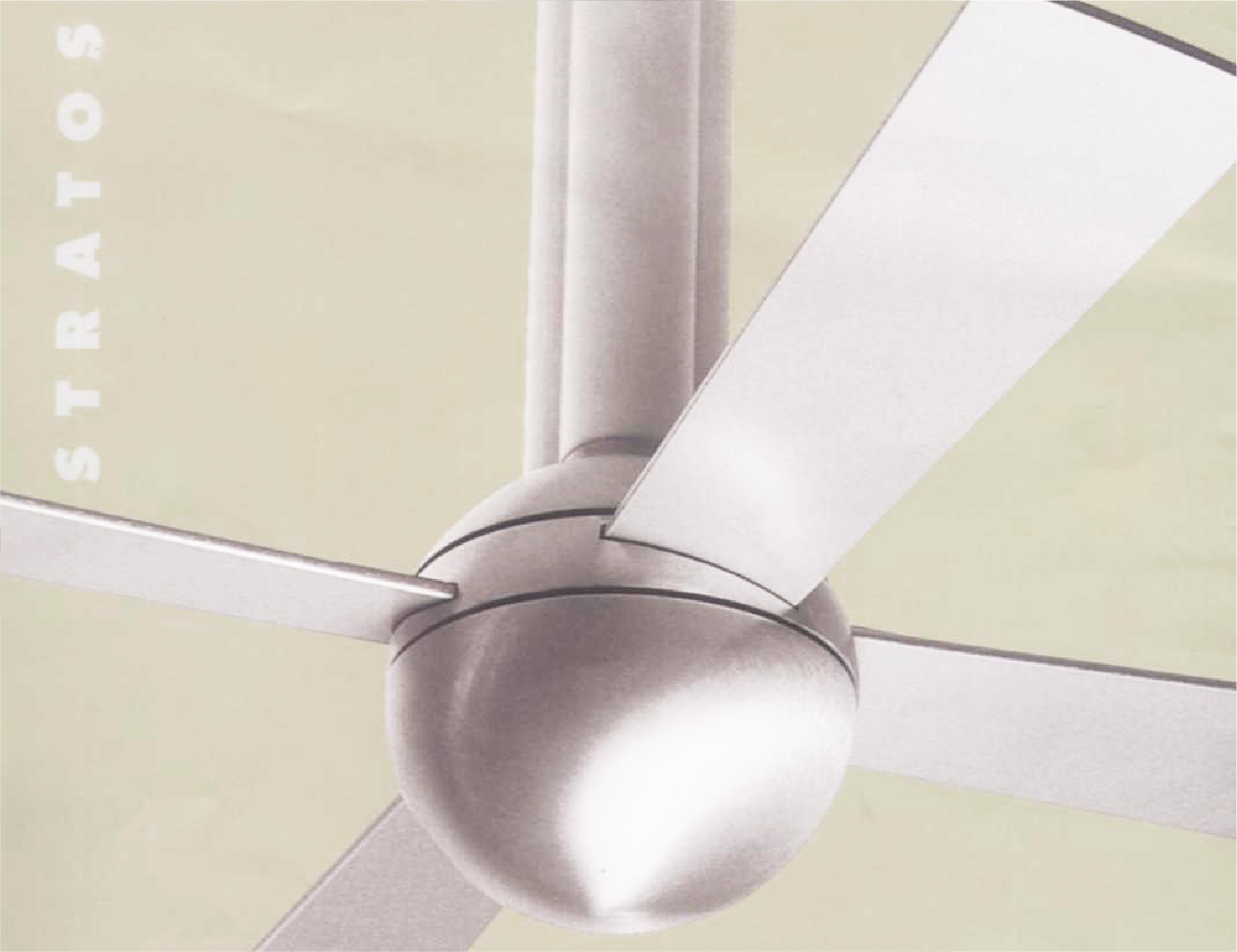

Introduce The Modern Style

The post-modern classic ceiling fan was first designed and developed in 1990, which is our collaboration with Modern Fan Company, the originator of contemporary ceiling fans in the United States. The classic STRATOS fan is still popular with its timeless contemporary forms until now. Moreover, this collaboration was the turning point for Halsey to start designing high-end ceiling fans.

2007

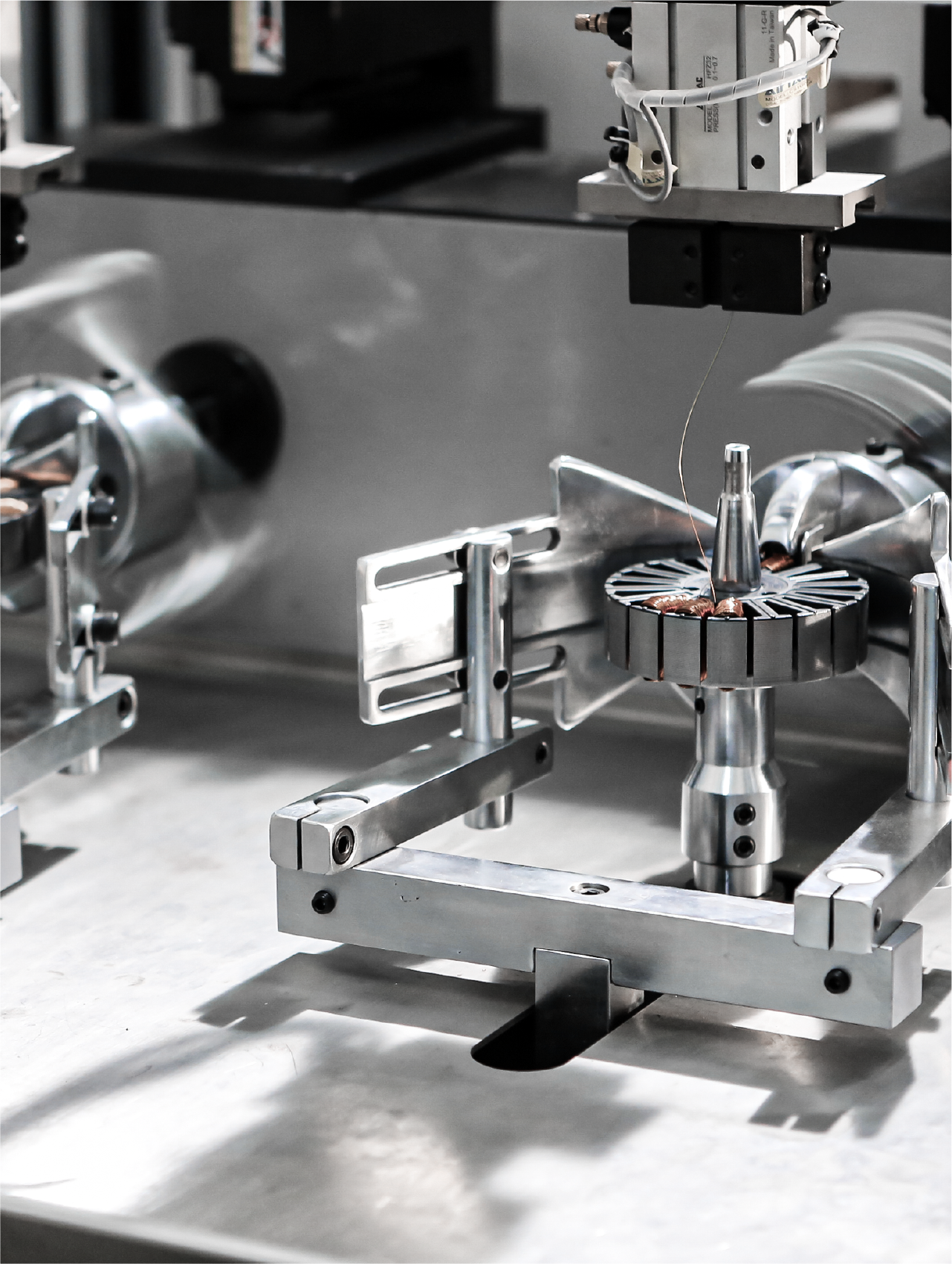

State of The Art Technology

In 2007, Halsey introduced robotic arm equipment with high precision from ABB Sweden, which not only improves the quality of manufacturing and technology but also turns the page of modern automation technology and innovation. With precise production lines and development strategy, we’re able to increase our production capacity tremendously.

2012

Timeless Design

Since revealing the new chapter of the design form in 2012, we have breakthrough the traditional design concept of ceiling fan products. We aim to create products that focus on simple design and bring a quality of comfort to daily life which makes it simple for customers to create a cohesive and sophisticated look in their daily homes.

2000

Begin of The New Era

China Factory Expansion

In the year 2000, we established a subsidiary in China to expand our production plant and attract more partners to join this family. The expansion of the plant improves production and meets the delivery needs, in addition to providing local employment opportunities and reflecting our social responsibilities.

2019

All New Brand Images

In 2019, we reassess our brand image and integrate design aesthetics into our product form and design minimalist products that are suitable for modern spaces. At this moment, we're able to present a new brand image by breakthrough the existing framework.

2018

Creation of Kubrick

We begin from an original intention, focus on practical and aesthetic design as our fundamental, and concern the value of our brand. In 2012, we established our own brand KUBRICK, endowed with a unique aesthetic and hope to build convenience for home life. We aim to create the core value through our product in every customer’s daily life.

2012

A Fresh Breeze

The Wilderness Imagination

KUBRICK combines craftsmanship and technology to reform the essence of solidwood; from the visual to the user experiences which approach the ideal design imagination. The fan blade shape conveys the warmth of solidwood and that is all the reason we aim to present the design through different materials so that the craftsmanship heritage can be integrated into each daily life experience.

2012

The New Warehouse

Logistic System

By implementing the efficient system of material management, we aim to elevate our integrated warehouse system and effectively enhance production efficiency.

Through streamline production, it helps to increase the production capacity without compromising the quality.

2022

Every Part Tells A Unique Story

Every detail is compelling a unique story of the product itself. The product design combined with the craftsmanship in order to create our imagination without limitation. We not only give a new lease of life to our products with our years of aesthetic experience but also endeavor the ideation into our design progress and let the creations could have more connection with the user in space.